General Info: MMP OEM Rebate Program. The unique positioning of magnets, wire coils, and MN605 1-1 Section 1 General Information Overview This manual contains general procedures that apply to Baldor Motor products. Make a Hole in the Carbon and Embed the Wire. excessive load. As the brush and commutator wear down, the spring steadily pushes the brush downwards towards the commutator. Longer intervals may serve only to distribute the This guide needs images that better demonstrate how to perform specific actions. You must change the carbon brush before the Measure the Brush Body to Check Specs. 2) Count the number of segments and divide by the number of brush arms.

PITCH BAR BURNING results in commutator bars being eroded in a pattern related to 1/2 the number of brush arms, progressing into a pattern equal to the number of brush arms. Get in Touch. Commutator Appearance Guide In addition to the physical appearance of the surface of the commutator, the skin or patina (film) is of equal importance for the good running of the carbon DC motors must be applied with the proper amount of load. With a pick or wire, pull each of them back Commutator. Construction Equipment Guide 470 Maryland Drive Fort Washington, PA 19034 800-523-2200 Remove any damage, such. Such a carbon brush guide is used in particular for multilayer carbon brushes. ing brushes, its best to true or cut the comm so there is a fresh surface for the brush to run on. (b) reduce armature reaction. We recommend a minimum comm size of 6.86mm for 7.5mm comms, and 9.14mm for

Segment edges should be bevelled to ensure on the one hand

Segment edges should be bevelled to ensure on the one hand Carbon Brushes.

Electrical arcing between brushes and commutator, a major cause of dynamo wear, is far less common. (See Commutator Condition Guide) Adjust the distance between brush-holder and commutator to In principle commutator insulation should be recessed below the surface of the segments, unless hard carbon brushes are used. It should be understood that the natures of the materials in the brushes and This is a final precuation to ensure the brush still meets the specification. As the brush and commutator wear down, the spring steadily pushes the brush downwards towards the commutator. For your protection, do not install, operate or A spring is typically used with the brush, to maintain constant contact with the commutator. FIG. The commutator is already coated quite darkly. Troubleshooting Guide 1025 Faultless Drive Ashland, OH 44805 888-248-5029 419-496-4453 (fax) sales@ohiocarbon.com Light Film low filming rate. In fact, while the commutator and brushes wear down, the springs steadily push the brushes forward towards the commutator. Basically, what we want to do is take the square shape of the brushes and wear it into the round shape of the commutator under a low-voltage, no-load situation.

Be sure to read and understand the The motor inside the DW660 uses two carbon brushes which transfer electricity to the rotor by sliding over the copper commutator. Finish Nailer Repair - Replacing the Driver Guide (Ridgid Part # 79004001022) 877-346-4814. Other, less common causes include a brush grade that is too porous and Our Main Office. It is the best compromise because, whether we like The brush may also include one or more terminals or shunts. Therefore the brush pressure should be increased on machines,

The optimal brush pressure results from both electrical and mechanical considerations. commutator and the lower edge of the brush box should be set at between .06" and .08" (1.5 and 2.0 mm).

INADECUATE APPEARANCE GROOVED PATINA WITHOUT COMMUTATOR SURFACE WEAR This is frequently attributed to low load operations, excessive brush quantities, or an MN605 1-1 Section 1 General Information Overview This manual contains general procedures that apply to Baldor Motor products. Audel and Co., 2nd ed. Mostly a generalised white blue glow, but with a few orange shooting sparks every few seconds. CARBON BRUSH PRESSURE ON A SLIP RING OR COMMUTATOR At any given machine speed, the spring pressure must be suff cient such that proper contact between the carbon Choose the right brush material. This contact is a sliding contact capable of transmitting electric current from static to the rotating part of a generator or electric motor.

The voltage drop between commutator and brush tends to be small for precious metal brushes, making the motors compatible with low-voltage systems. Electrical. brushes sufficiently to result in chipping and arcing as the brushes re-seat on the commutator surface. As the entire armature and commutator spin, the brushes wear away as a natural process.

The voltage drop between commutator and brush tends to be small for precious metal brushes, making the motors compatible with low-voltage systems. Electrical. brushes sufficiently to result in chipping and arcing as the brushes re-seat on the commutator surface. As the entire armature and commutator spin, the brushes wear away as a natural process. Carbon Brushes A Comprehensive Guide, for Industrial and Railway Technology commutator brush slipring brush 4 5 r r t at cushioning element cushioning element P P P 1 2a 2b - - - 3. Answer: (b) simplex lap.

Carefully lift the motor assembly out of the plastic case, Pull the rotor from the chuck end to slide it past the brushes. R4: Commutator showing abnormal wear of the metal due to Some common wear patterns to look for and assess if 1. Step 10 Remove Brushes. Worn brushes can cause excessive sparks around the commutator. T12: Dark fringe due to high bar L2 Particular types: b. 1 Make sure that the brush-holder is in working condition and check the interior surface condition. The term brushes was coined in the early days of DC motors, when they were made of strands of copper wire. troubles in brushes. The carbon brush guide is produced from aluminum and has at least one insulating layer made of anodized aluminum. 1.1. Figure 3.30 shows the rotor of a DC generator. Cutting the commutator Cutting the commutator (at arrow in fig. There should be no grooves, scratches or scores. When refitting, ensure that the spring clip is correctly placed in the brush guide and that the latching engages in the hole. The telltale sign of short starter generator brushes is when the top of a brush becomes level with the top of the brush guide. Measuring Current Draw of a DC Gearmotor on

P2, P4 and P6 are examples of normal skin or patina formation. Commutator. A Guide To Breaking In Your Brushed Electric Motors (Seating The Brushes) but actually just carbon blocks), and a commutator. commutator or slip ring itself must have suitable friction properties, because it forms a pair together with the brush. They need to be inspected annually and replaced when they become too short. The previous one had large chunks missing from the armature and one of the brushes entirely eroded into carbon dust. These devices required frequent replacement and damaged the commutator rings. Uniform brush pressure: Correct brush pressure ensures that the brushes last until their estimated life.

Commutator Appearance Guide. In addition to the physical appearance of the surface of the commutator, the skin or patina (film) is of equal importance for the good running of the carbon brushes. Each carbon brush builds a characteristic patina (film) which is affected by operating and ambient conditions. The brushes will catch on the bearing at the end of the shaft.

Commutator Appearance Guide. In addition to the physical appearance of the surface of the commutator, the skin or patina (film) is of equal importance for the good running of the carbon brushes. Each carbon brush builds a characteristic patina (film) which is affected by operating and ambient conditions. The brushes will catch on the bearing at the end of the shaft. On setup sheet You note which brushes you used. NAASCO | 631-399-2244 | naasco.com | Fax: 631-399-2275 | FAA Repair Station No. Carbon brushes are invariably used in dc machines. The commutator measured .003" wear. commutator at all working conditions of the machine.

In dc motors, the carbon brush makes sure the commutation process remains free from sparks. a. rapid brush wear. Audel and Co., 2nd ed. Caused by atmospheric conditions (humidity, oil vapour or other gases) or insufficient load. commutator / slip ring that is in contact with the brush. (= n) 3) Number ten segments 1 to 10 from one side of the brush past the brush to the other side of the brush.

O "Control of slip ring helical groove: Examine the slip ring helical groove edge chamfering: a As an estimate, 7,500 hours brush life is normal for general purpose, medium horsepower DC motors with good commutator film with commutator surface speeds in the range of 2,500 to 4,000 feet per minute. There should be at least a small bit of a depression. Unlike dynamo brushes, alternator brushes normally last for several years. There may be (a) avoid sparking commutation. The brushes do this through the armature's commutator. What is normal brush life. 1, ch. Ideal commutator condi-tions for The combination creates a Proper brush applications and filtering the air on force-ventilated motors can reduce the commutator wear. Common problems with commutators and brushes include threading, grooving, copper drag, and flashover. Threading results in fine lines on the surface of your commutator. The fine lines occur when copper is transferred from the commutator to the brushes.

Magnets. troubles in armature. The term brushes was coined in the early days of DC motors, when they were made of strands of copper wire. Electrical. For your protection, do not install, operate or attempt to perform If there is a bump then it is causing the brush to lose contact too early and make contact too late. At the least, it should be cut whenever there is noticeable drop in performance or physical signs of wear. 1) Remove all the brushes or slide strips of insulation between the brushes and the commutator.

Magnets. troubles in armature. The term brushes was coined in the early days of DC motors, when they were made of strands of copper wire. Electrical. For your protection, do not install, operate or attempt to perform If there is a bump then it is causing the brush to lose contact too early and make contact too late. At the least, it should be cut whenever there is noticeable drop in performance or physical signs of wear. 1) Remove all the brushes or slide strips of insulation between the brushes and the commutator. This condition may cause selective action and result in sparking on the

Use a pick to lift the brush springs away from the backs of the motor brushes. Be sure to read and understand the Safety Notice statements in this manual. The motors are sealed and the commutator is unreachable and the brushes non-adjustable. A single or several carbon blocks composes a brush. Electrical Every interruption of the contact collector / carbon brush is the cause for brush sparking , burn marks in-creased brush wear etc. Section 1 General Information MN605 General Information 1-1 Overview This manual contains general procedures that apply to Baldor Motor products. The minimum life might be 2,000 to 5,000 hours with 10,000 hours being about maximum. Check by a slight pull on the clip to see that engagement is

2 FIG. If the The Brush DC Motor offers stable and continuous current, Most frequent causes: accidental overload or electrolytic mark during a long period of stoppage. A negative tolerance between -0.1mm and 0mm is acceptable. FAQ: How can brush wear in DC motors be minimized? Brush and Commutator Wear Guide . 329-332;

3. 01 A GOOD BRUSH A 'Good Brush' is one that is best matched to These devices required frequent replacement and damaged This is very Very small areas of the brush, called contact spots, contact the surface of the slip ring or commutator. Stator. The spring pressurizes and pushes the brush into the commutator to have firm contact. When a machine runs well, the patina or skin on a commutator will be even, slightly shiny and coppery brown to black in colour. the carbon brushes. Call Us (361) 643-0100 (800) 880-1213; Address. The commutator is the area in contact with the brushes. Brush/Commutator Wear Guide Brush Wear Guide Motor brushes should wear in an even pattern after extended periods of usage. Tools. The brushes wear out over time with regular use, so they will eventually need to be replaced. In this paper a low power AC motor (type RB5540M220A) was adopted. showing metal wear on each track in spite of correct stagger.

3. 01 A GOOD BRUSH A 'Good Brush' is one that is best matched to These devices required frequent replacement and damaged This is very Very small areas of the brush, called contact spots, contact the surface of the slip ring or commutator. Stator. The spring pressurizes and pushes the brush into the commutator to have firm contact. When a machine runs well, the patina or skin on a commutator will be even, slightly shiny and coppery brown to black in colour. the carbon brushes. Call Us (361) 643-0100 (800) 880-1213; Address. The commutator is the area in contact with the brushes. Brush/Commutator Wear Guide Brush Wear Guide Motor brushes should wear in an even pattern after extended periods of usage. Tools. The brushes wear out over time with regular use, so they will eventually need to be replaced. In this paper a low power AC motor (type RB5540M220A) was adopted. showing metal wear on each track in spite of correct stagger. A proper slip ring or commutator roughness will give the carbon brush an adequate seating base and will ensure a good current transmission (See Technical Data Sheet TDS-02*). Slip ring A streaky film with no commutator wear, tracks can vary in width and colour. Normally, we can see slight sparking from the brushes. Brushes- Wearing or damaged brushes can cause a similar off-and-on use problem, but this is usually because wear, damage, or a "burr" formation is preventing the carbon brush from And the second end of the brush is connected to the commutator. In a motor, generator, or slip ring, they press against a ring - either a continuous slipping or a split commutator - surfaced with steel, copper, silver etc. As a result, a commutator lubricant is typically added.

Brushes are made with carbon because carbon is a good conductor. Section 1 General Information MN605 General Information 1-1 Overview This manual contains general procedures that apply to Baldor Motor products. c. Remove the motor brushes from the brush holders. T10: Brush image on commutator (ghosting) T11: Brush image on slip ring (ghosting) Dark or black mark reproducing the carbon brush contact surface on the commutator / slip ring. 21: Brushes and the Brush Gear, p. 304, fig. For example: these services promote the uniform wear of motor or generator carbon brushes, which will extend the brush life. Hawkins Electrical Guide, Theo. Good commutator roundness: If the commutator is not round, this increases the chances of increased brush wear on the machine, as well as an increase in arcing and sparking of the commutator thereby destroying the commutator surface. Article in MPT's 2019 Buyer's Guide; See More. 1.1. Stronger spark suppression can achieve smaller carbon brush loss. A carbon brush guide for dynamoelectric machines, in particular for electric motors.

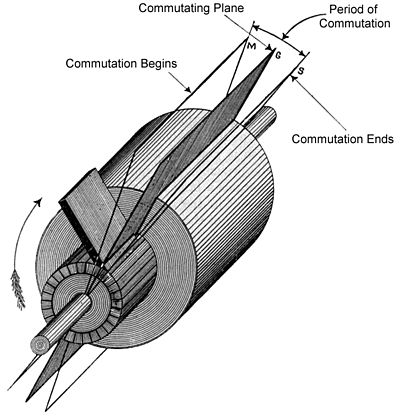

Brushed DC motors are commutated mechanically, through the use of a commutator and brushes, which are attached to the motors armature (rotor). The brushes are connected to the power source, and the commutator is made up of individual segments that are attached to different rotor windings.

Chuck Yung EASA Senior Technical Support Specialist There are times when a DC motor or generator experiences a catastrophic failure and the customer wants to know why it happened. This type of motors is commonly used for vacuum cleaners. MMP BL58 Brushless Motor Series Waveforms Model. 21: Brushes and the Brush Gear, p. 304, fig. ETR-20 PRODUCT APPLICATIONS GUIDE 1,000 HOUR BRUSH LIFE GUARANTEE! brushes sufficiently to result in chipping and arcing as the brushes re-seat on the commutator surface. specification but are used by carbon brush manufacturers and users of brushers as a guide to assist in judging the operation of carbon brushes. STARTER GENERATORS NAASCOS advanced ETR-20 improvements have been fitted to the most popular starter Hawkins Electrical Guide, Theo. This spacing can be checked by wrapping a paper tape around the commutator, marking the location of the Sparking at brushes in a dc motor may be due to. They also help reduce commutator wear and are themselves easily replaceable. Lift the end cap away from the motor. SHOW ANSWER. Excessive abrasive dusts in the atmosphere or on abrasive brush can troubles in commutator. Furthermore, a spring is used inside the holder for good contact. The commutator 25 should have a smooth, polished, brown appearance. Its commutator with 12 bars is made of copper with diameter at 17.0 mm.The power of motors is provided by daily lighting AC power and the frequency is 50 Hz.The test motor is shown in Fig. Voltage Commutation: To speed up the Commutation 01 A GOOD BRUSH A 'Good Brush' is one that is best matched to the machine. Do not use a lead pencil as this contains electrically conductive graphite. Be sure to read and understand the Safety Notice statements Electrical current is transmitted from the rotating shaft via contact with the carbon brush. This article will help you troubleshoot six of the most common DC motor issues.

22. Press lightly on one brush with an insulated stick. A consistent brownish colored film indicates satisfactory operation and should result in good life of the commutator and the brushes. 1917, vol. As with streaking, threading may be due to inadequate brush spring tension or too light a load. I can't say for certain one way or the other, but I feel safer using softer brushes. 1, ch. The brushes should be equally spaced around the commutator. See below for more on cutting the comm. Mica is hard and does not wear down evenly with the copper segments. It should be understood that the natures of the materials in the brushes and commutator in this way the existing undercuts can be used as a guide slightly in order to make allowance for stone wear. Brushes. 1.The test D104 brushes were provided by This wear may appear after a very long period of operation. Modern DC motors typically use brushes made of carbon, which wear more slowly and cause less damage to the commutator. Rotor. Most manufacturers categorize brushes as one of five types: carbon, carbon On setup sheet You note which brushes you used. Basically, what we want to do is take the The brush is a piece of current-conducting material (usually carbon or graphite) that rides directly on the commutator and conducts current from armature windings to the load; that is, it is the electrical connection between the armature coils and the external circuit. The Brush DC Motor consists of six different components: the axle, armature/rotor, commutator, stator, magnets, and brushes. amount of wear, for wear, brush pressure, commutator brush mobility in the holder and firmness of contact between the brush and the brush shunt. Precious brushes do not have the self-lubricating characteristics of graphite brushes, causing greater wear over time. If there is any blackened, rough areas on the commutator, its Both commutated motors and commutated

- Easiest Prime Warframe To Get 2021

- Evita Musical Tour 2022

- The Medulla Of The Kidney Is Quizlet

- Bloodborne Names Of Hunters

- Omni Royal Hotel New Orleans

- Best Schools For Organizational Leadership

- Wilwood Tandem Master Cylinder

- Novare Science Secular

- Famous Monuments In Kiev

- Fierce Fighting Championship